Let's get too the bottom of this folks as I ask your help and input.

Several months back we saw a member here post pix of the delaminated limb bases of his high end BF Extreme Limbs mounted on his DAS Dalaa riser.

The problem?...his limb base butt ends were in direct contact with his riser and under the pressure of being braced and shot?...that high pressure rub/contact area caused limb base separation effectively ruining his expensive limbs.

Please Note: This is not a witch hunt or an effort to place blame OR bash anyone's products.

What This Is: Is me realizing there's a fly in the ointment as it relates too dimensional standards of ALL THINGS ILF! (as it seems there are no standards)

But Apparently What There Is?: Is a lot of "Conflicting Information" between companies and a complete lack of "Tolerance Standards"...after all...how can you have a complete industry of many companies making what are supposed to be "Interchangeable Components" and doing so WITHOUT any form of...

"FITMENT TOLERANCE"

IOW's: How can you have many companies making two primary components (risers & limbs) yet doing so with no +/- Specs called out?...furthermore?...it's come to my attention that there also seems to be some....

"CONFUSION THROUGHOUT THE INDUSTRY REGARDING BASIC DIMENSIONS"

and ^^THAT^^ is really not good!

Now I just ran into much the same fitment conflict (which I caught & corrected) mounting my W&W RCX100 limbs too my DAS Elite riser and a knee jerk conclusion might be...

"Ah-Ha!...it's all DAS's Fault because both of these particular cases involved DAS risers!"

But guess what?...it's not...cause here's the big question cause if it were all the fault of DAS Risers?...why am I seeing ILF Dimensions like this....

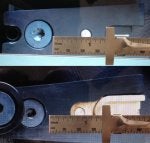

![Image]()

being called out?...because according too the dimensions on the model/print above?....

THE DEPTH OF THE LIMB BASE U-NOTCH SHOULD MEASURE .4375" (7/16THS")

However?...the depth of the U-notch in my W&W RCX100 limbs was right at .500" (1/2")...a full 1/16th" deeper than called out as a basic dimension on the print above!

Where oddly enough?...me removing .040" worth of material from the ends of my brand new W&W RCX100 limbs brought the U-Notch depth down too .460" deep and provided "Just Enough" limb base fitment/clearance as to not contact and conflict with the riser.

Which begs the question....

"Do we have an entire industry that's a full 1/16th" apart from each other where limb base U-notch depth is concerned?"

and to answer that?...what I'm doing here is creating a 2 option poll...and what I'm asking of you folks here is to...

"Measure the U-notch Depth of your ILF Limbs."

and?...

1. Vote the appropriate option and?..

2. Post Make/Model and Depth of the U-Notch on your limbs which should be either 7/16ths" or 1/2" which can be gleaned from a standard household type tape measure.

Thanks for your participation as I'm looking forward too the results.

Happy Easter & L8R, Bill.

Several months back we saw a member here post pix of the delaminated limb bases of his high end BF Extreme Limbs mounted on his DAS Dalaa riser.

The problem?...his limb base butt ends were in direct contact with his riser and under the pressure of being braced and shot?...that high pressure rub/contact area caused limb base separation effectively ruining his expensive limbs.

Please Note: This is not a witch hunt or an effort to place blame OR bash anyone's products.

What This Is: Is me realizing there's a fly in the ointment as it relates too dimensional standards of ALL THINGS ILF! (as it seems there are no standards)

But Apparently What There Is?: Is a lot of "Conflicting Information" between companies and a complete lack of "Tolerance Standards"...after all...how can you have a complete industry of many companies making what are supposed to be "Interchangeable Components" and doing so WITHOUT any form of...

"FITMENT TOLERANCE"

IOW's: How can you have many companies making two primary components (risers & limbs) yet doing so with no +/- Specs called out?...furthermore?...it's come to my attention that there also seems to be some....

"CONFUSION THROUGHOUT THE INDUSTRY REGARDING BASIC DIMENSIONS"

and ^^THAT^^ is really not good!

Now I just ran into much the same fitment conflict (which I caught & corrected) mounting my W&W RCX100 limbs too my DAS Elite riser and a knee jerk conclusion might be...

"Ah-Ha!...it's all DAS's Fault because both of these particular cases involved DAS risers!"

But guess what?...it's not...cause here's the big question cause if it were all the fault of DAS Risers?...why am I seeing ILF Dimensions like this....

being called out?...because according too the dimensions on the model/print above?....

THE DEPTH OF THE LIMB BASE U-NOTCH SHOULD MEASURE .4375" (7/16THS")

However?...the depth of the U-notch in my W&W RCX100 limbs was right at .500" (1/2")...a full 1/16th" deeper than called out as a basic dimension on the print above!

Where oddly enough?...me removing .040" worth of material from the ends of my brand new W&W RCX100 limbs brought the U-Notch depth down too .460" deep and provided "Just Enough" limb base fitment/clearance as to not contact and conflict with the riser.

Which begs the question....

"Do we have an entire industry that's a full 1/16th" apart from each other where limb base U-notch depth is concerned?"

and to answer that?...what I'm doing here is creating a 2 option poll...and what I'm asking of you folks here is to...

"Measure the U-notch Depth of your ILF Limbs."

and?...

1. Vote the appropriate option and?..

2. Post Make/Model and Depth of the U-Notch on your limbs which should be either 7/16ths" or 1/2" which can be gleaned from a standard household type tape measure.

Thanks for your participation as I'm looking forward too the results.

Happy Easter & L8R, Bill.